What is IIoT and How it Works

Introduction

In an age where data is hailed as the new currency, industries are undergoing a digital revolution that promises to redefine how they operate and usher in a new era of unprecedented efficiency and connectivity. At the heart of this transformation lies the Industrial Internet of Things (IIoT), which is a vital element of Industry 4.0, a powerful and dynamic technology that holds the potential to reshape the industrial landscape. This article delves into the fascinating world of IIoT, unraveling its core concepts, highlighting its distinctions from the broader Internet of Things (IoT), and exploring its real-world applications driving innovation across various sectors.

What is IIoT

The Industrial Internet of Things (IIoT) represents the extension and integration of Internet of Things technologies within industrial sectors and applications. With a strong focus on machine-to-machine communication, big data, and machine learning, IIoT empowers industries and enterprises to enhance their operational efficiency and reliability. It encompasses various industrial applications, including robotics, medical devices, and software-defined production processes.

What sets IIoT apart is its unique convergence of information technology (IT) and operational technology (OT). OT involves networking operational processes and industrial control systems, encompassing HMIs, supervisory control, SCADA systems, DCSs, and PLCs. This comprehensive approach ensures that IIoT plays a pivotal role in reshaping industrial processes and facilitating data-driven decision-making.

What is IoT

IoT is a revolutionary concept encompassing a complex network of physical objects called “things.” These objects are equipped with sensors, software, and various technologies to enable Internet connectivity and data exchange with other devices and systems. IoT devices range from everyday household items to various interconnected tools and gadgets. Presently, there are more than 15 billion connected IoT devices, illustrating the extensive integration of this technology into our daily lives.

What is the difference between IoT and IIoT?

The fundamental distinction between IoT and IIoT lies in their primary objectives: IoT is primarily designed for consumer applications, enhancing convenience and lifestyle, while IIoT is focused on elevating safety and efficiency within industrial production environments.

There are more differences between IoT and IIoT

What are the Similarities between IIoT and IOT

IoT and IIoT both share common concepts and technologies of smart equipment connectivity and cloud computing to establish a system (always online) that collects data to help users make informed decisions. Some of the few tangible similarities between IoT and IIoT include the following:

- They both necessitate a cloud computing framework.

- They both necessitate Machine Learning (ML) and Artificial Intelligence (AI) to ensure smart decision making.

- They both utilize common input/output devices, for instance, sensors, cameras, microphones etc.

- Affordable and high speed internet connection is an essential resource for both IOT and IIoT.

- Both IoT and IIoT systems are designed to scale efficiently, accommodating a growing number of devices and data volumes without significant challenges.

- Energy efficiency is a shared concern in IoT and IIoT, with a focus on extending the battery life of connected devices and minimizing energy consumption.

- Security is a common priority in both IoT and IIoT, with a focus on implementing robust measures to protect data and devices from unauthorized access and potential threats.

- Both IoT and IIoT systems often feature user friendly interfaces, allowing users to interact with and control connected devices through web or mobile applications.

How does IIoT work

IIoT, or the Industrial Internet of Things, works by connecting smart devices to create systems that collect, share, and analyze data. Here's how it simplifies:

- Connected Devices: Smart devices can sense, communicate, and store information about themselves.

- Data Communication: These devices use networks, both public and private, to transmit data.

- Analytics and Applications: Software processes this data to provide useful insights.

- Data Storage: Information is saved for future reference.

- People: Humans use this data to make decisions and optimize processes.

These edge devices and intelligent assets transmit information directly to the data communications infrastructure, where it's converted into actionable information on how a certain piece of machinery is operating. This information can be used for predictive maintenance, as well as to optimize business processes.

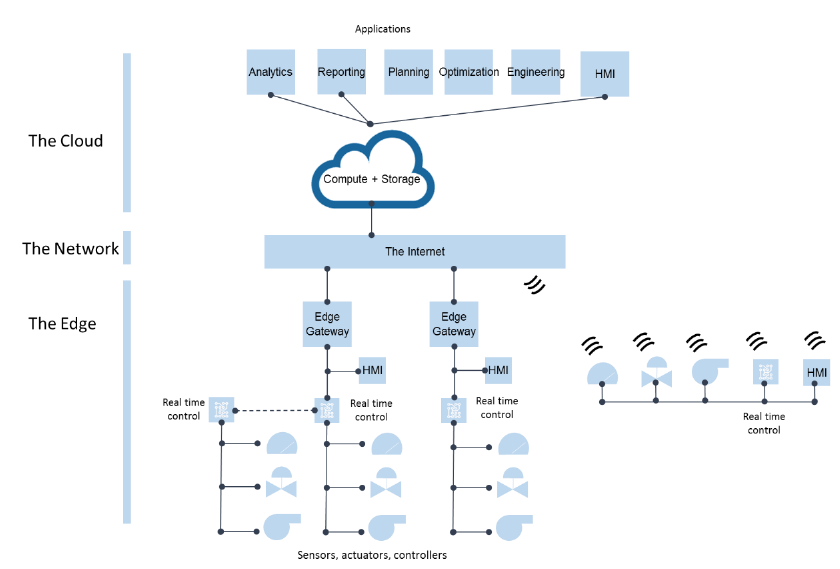

IIoT Architecture

To further explain how IIoT works, this is a typical IIoT architecture outlines the organization of digital systems, enabling network and data connectivity among sensors, IIoT devices, data storage, and other layers. A comprehensive IIoT architecture should incorporate the following essential layers:

Edge Layer (Sensors, Actuators, and Controllers):

- Role: The edge layer serves as the frontline of the IIoT architecture, where data is born. It includes a network of sensors, actuators, and controllers located as close to the data source as possible.

- Functionality: Sensors gather data, whether from the environment or the objects they monitor, and convert it into actionable information. Actuators play a vital role in regulating and influencing processes within the measured environment, adjusting physical conditions as needed. This layer ensures data collection and initial processing.

- Examples: Devices in this layer can range from wireless sensors, robotic cameras, and microphones to various meters and monitoring systems.

Network Layer:

- Role: The network layer acts as a crucial intermediary, ensuring the seamless flow of data between the edge and the cloud layers.

- Functionality: This layer serves as the gateway that aggregates sensor data and converts it into digital streams for further processing. It routes this data via the internet, optimizing it for future analysis in the cloud. It is essential for managing the massive and continuously changing data streams generated by sensors.

- Importance: Gateways are indispensable because they bridge the gap between the data intensive edge and the cloud, making data processing more manageable and efficient. Additionally, they may include analytics and security features to enhance data handling.

Cloud Layer:

- Role: The cloud layer serves as the central hub for comprehensive data processing and storage.

- Functionality: At this stage, the digitized and aggregated data from the edge and network layers undergo in depth analysis, using advanced analytics, machine learning, and data visualization tools. This layer combines data from various sources and generates valuable insights.

- Benefits: Comprehensive processing in the cloud allows you to extract deeper insights from the data, which might not be immediately available at the edge. It is where you can make use of advanced analytics and artificial intelligence to gain a deeper understanding of your operations, enabling data driven decisions.

In summary, the IIoT architecture consists of three vital layers: the Edge Layer for data collection and initial processing, the Network Layer for data optimization and routing, and the Cloud Layer for in depth analysis and insights. This structured approach enables efficient data handling, ranging from quick and immediate responses at the edge to deeper insights and comprehensive processing in the cloud.

What are the benefits of IIoT

The IIoT brings many advantages to companies, and here are some of the main ones according to the consulting firm Morgan Stanley:

- Boosts Efficiency: IIoT enables automation and continuous monitoring of equipment and processes. This leads to improved operational efficiency, as real time data allows for data driven decisions and remote monitoring.

- Increases Production: IIoT connected manufacturing processes enhance equipment usage and performance. By maximizing machine effectiveness and freeing up employees from repetitive tasks, production capacity can be increased.

- Reduces Errors: Automation in industrial operations minimizes human related inefficiencies, resulting in fewer defects in products. This leads to improved customer satisfaction and brand reputation.

- Predicts Maintenance Needs: IIoT sensors help implement predictive maintenance strategies by analyzing production data for patterns and early issue detection. This proactive approach prevents asset failures, reduces costs, and minimizes downtime.

- Enhances Worker Safety: IIoT contributes to a safer work environment with sensors monitoring employee and workplace safety. In case of incidents, integrated safety systems can trigger alerts and actions, ensuring a swift response and providing insights for future prevention.

- Saves Energy Costs: IIoT allows for the continuous monitoring and optimization of energy consumption, which can reveal inefficiencies and lead to cost savings. This extends to regulating factors such as temperature, water usage, humidity, and lighting.

- Improves Field Services and Customer Experience: IIoT can enhance field services by providing real time data and insights. This leads to improved customer experiences as companies can offer more efficient services and respond to customer needs promptly.

Is IIoT secure

Security is a top concern when it comes to the Industrial Internet of Things. While IIoT offers numerous advantages to businesses and industries, it also introduces potential security risks that need to be addressed. The interconnected nature of IIoT systems and the vast amount of data they generate can be attractive targets for cyber threats.

To ensure the security of IIoT, organizations must implement robust security measures that encompass various aspects, including:

- Data Encryption: Protecting data with strong encryption methods to prevent unauthorized access.

- Access Control: Implementing access policies to ensure that only authorized personnel can interact with IIoT systems and devices.

- Authentication: Verifying the identity of users and devices to prevent unauthorized access.

- Continuous Monitoring: Keeping a watchful eye on the IIoT network to detect and respond to security incidents in real time.

- Secure Device Management: Ensuring that IIoT devices are regularly updated and patched to address vulnerabilities.

- Network Segmentation: Isolating critical parts of the network to limit the impact of a potential breach.

- Compliance with Industry Standards: Adhering to security best practices and standards specific to the industry.

While IIoT security is a significant challenge, it's essential for protecting industrial processes, sensitive data, and critical infrastructure. Organizations must prioritize security measures to mitigate the risks associated with IIoT and build a secure foundation for their industrial operations.

Challenges of IIoT

As previously discussed, security is a primary challenge in the realm of Industrial Internet of Things However, there are several other critical challenges that organizations face when implementing IIoT solutions:

- Integration: Integrating IIoT with current systems can be quite complex. The various data sources and the need to make this data useful present significant challenges. To overcome this, companies should invest in strong integration platforms that can handle the complexities of IIoT data. Moreover, ensuring that different devices and platforms can easily share data (interoperability) is crucial.

- Data Management: Managing data effectively is a major challenge in IIoT. IIoT systems produce large amounts of data that need to be stored, processed, and analyzed efficiently. To address this, companies should invest in flexible data storage solutions and advanced analytics tools. It's also essential to have strong data governance rules to maintain data quality and meet regulatory standards.

- Skills Gap: The fast paced growth of IIoT technology has created a shortage of experts who can develop and run IIoT systems.

- Interoperability: Not all IIoT devices and solutions work well together or with your business apps. When you add new hardware or software, it can set off a chain reaction of changes needed to make everything work. Interoperability is an issue for IIoT makers, too. Some IIoT tech relies on open source technology. That's fine, but if there's no universal standard, different businesses and countries can use their versions. This can make it hard to use tech from other companies or launch IIoT solutions in new places.

- Scalability: As IIoT networks grow, scaling them to accommodate an increasing number of devices and data volumes can be challenging. Ensuring that the network infrastructure can handle this growth is crucial.

- Bandwidth availability: In the Industrial Internet of Things, a challenge is limited bandwidth. It's like when too many devices share the same Wi Fi frequency in an apartment building, causing signal interference. Similarly, IIoT devices in close proximity can interfere with each other due to limited radio frequency bandwidth. This challenge underscores the need for efficient bandwidth management in IIoT to avoid signal issues and ensure smooth operations.

IIoT Applications

Businesses are increasingly recognizing that the advantages of IIoT far outweigh the associated costs, leading to its adoption across a wide range of industries. Here's a closer look at how IIoT is making its mark in various sectors:

- Logistics: Logistics companies are harnessing the power of IIoT to connect humans and machines. Drone technology, driven by IIoT, receives information from human controllers, allowing for data collection and expedited deliveries.

- Manufacturing: Manufacturers are integrating IIoT powered devices, sensors, and machinery into their factories to gain real time insights into production processes. This enables them to identify areas for improvement and predict maintenance needs.

- Agriculture: Agtech companies are employing IIoT to develop fully automated tractors. These tractors rely on sensor technology to navigate fields, accurately place seeds, and compile geospatial data for analysis by farmers.

- Automotive: The automotive industry is leveraging IIoT to drive the growth of autonomous vehicles. Self driving cars use sensors to monitor their location and adjust routes based on real time traffic data.

- Construction: Construction businesses are utilizing IIoT's interconnected structure to monitor equipment and track project progress. This approach ensures adherence to safety protocols and compliance with industry regulations.

- Transportation: Transportation companies deploy IIoT sensors and devices to optimize routes and equipment utilization. This helps prevent spoilage of perishable goods and ensures efficient use of containers and vessels.

- Power: IIoT enables the segmentation of power grids into manageable sections, reducing the complexity of power management. It also facilitates automation of systems like lighting and HVAC when facilities are unoccupied.

- Wearables: Wearable technology combined with IIoT enhances safety in physically demanding environments. Wearables can alert managers to safety hazards and monitor employees' vital signs, ensuring their well being.

- Cybersecurity: IIoT's ability to connect devices across a network empowers companies to monitor endpoints and assets, enhancing cybersecurity. It enables early detection and mitigation of cyber threats.

- Robotics: Pairing robotics with IIoT enables the automation of machine processes, enhancing productivity and product quality. IIoT can also provide early alerts for machine maintenance, reducing downtime and costs.

Real life Business Examples of IIoT Applications

Real life business examples of IIoT applications:

- Fanuc: Predictive Analytics Fanuc, a robotics manufacturer, implemented predictive analytics using IIoT sensors to forecast equipment failures. Their zero downtime approach earned them the Supplier of the Year Innovation Award.

- Airbus: Smart Factory Airbus, a leading aircraft manufacturer, created a "Factory of the Future" with IIoT sensors in machines and workers' uniforms to enhance safety and reduce errors. They use smart glasses to simplify complex tasks.

- Maersk: Route Optimization Maersk, a global shipping company, employs IIoT to monitor shipments, minimize fuel consumption, and identify optimal routes, particularly in unpredictable sea conditions. Advanced software ensures cargo safety. Komatsu: Remote Monitoring Komatsu, a heavy equipment manufacturer, uses IIOT for remote monitoring. It connects robots to the internet, allowing centralized control, accident prevention, productivity enhancement, and safety assurance.

- Bosch: Inventory Tracking Bosch optimizes workflows with IIoT, including the Track and Trace program to locate tools efficiently. Sensors on tools improve inventory management and boost employee morale.

- John Deere: Self Driving Vehicles John Deere, a heavy equipment manufacturer, employs self driving tractors and high precision GPS systems to enhance safety, eliminate errors, and increase efficiency in their operations.

- North Star BlueScope Steel: Employee Safety North Star BlueScope Steel uses wearables, including specialized helmets and wristbands, to track employee safety. These devices provide real time health data and alert managers to potential hazards like radiation or toxic gases.

Who are IIoT vendors

In the realm of IIoT, a multitude of vendors provide cutting edge platforms and solutions:

- ABB Ability: ABB is a prominent player specializing in connectivity, software, and machine intelligence. Their solutions are tailored to streamline industrial processes and enhance operational efficiency.

- Aveva: Recently acquired by Schneider Electric, Aveva is at the forefront of AI, digital transformation, and IIoT. They develop robust platforms that cater to both original equipment manufacturers and end users, empowering them with the capabilities of the Industrial Internet of Things.

- Cisco IOT: Cisco is a recognized leader in the IIoT landscape, offering comprehensive platforms that cover network connectivity, connectivity management, data control, and exchange, along with cutting edge edge computing solutions.

- Fanuc: Fanuc is a renowned name in the world of robotics, automation, and advanced analytics. They leverage these technologies to provide innovative IIoT offerings, optimizing industrial processes and productivity.

- GE Predix Platform: GE's Predix Platform is a versatile IIoT software solution designed to facilitate seamless connectivity, optimization, and scalability of digital industrial applications. It's a comprehensive tool for industries aiming to harness the power of IIoT.

- Plataine: Plataine specializes in harnessing the potential of artificial intelligence to generate actionable insights within the manufacturing sector. Their IIoT solutions are focused on enhancing efficiency and decision making in industrial settings.

- Siemens Insights Hub: The Siemens Insights Hub offers an industrial IoT platform enriched with AI and advanced analytics. It's tailored to provide deep insights and intelligence for optimizing industrial operations, making data driven decisions, and driving productivity.

Additional notable IIoT vendors include Rockwell Automation, IBM, Microsoft Azure, AWS, and many more. These companies offer a wide range of solutions and services to cater to the diverse needs of businesses in the IIoT space.

What is the future of IIoT

The future of the Industrial Internet of Things holds significant promise and is poised for further transformation:

- Advanced Automation: IIoT will continue to drive automation in industrial processes, reducing the need for manual intervention. Automation will enhance efficiency, minimize errors, and lead to cost savings across various industries.

- 5G Connectivity: The rollout of 5G networks will enable faster and more reliable data transmission, allowing IIoT devices to exchange data in real time with low latency. This will further enhance the capabilities of IIoT systems.

- Edge Computing: Edge computing will play a crucial role in IIoT. Processing data closer to the source (at the edge) will reduce latency and enable real time decision making. This will be particularly vital for applications that require immediate responses, such as autonomous vehicles and robotics.

- AI and Machine Learning Integration: IIoT systems will increasingly incorporate artificial intelligence (AI) and machine learning (ML) algorithms to make sense of the vast amount of data generated. Predictive maintenance, anomaly detection, and data analytics will be significantly improved. Interoperability and Standards: Efforts will continue to establish universal standards for IIoT devices and platforms to ensure better interoperability. This will simplify integration and data exchange between different systems.

- Enhanced Security Measures: With the growing adoption of IIoT, the need for robust security measures will become even more critical. Advanced cybersecurity solutions will be developed to protect IIoT devices and networks from cyber threats.

- Sustainability: IIoT will contribute to sustainability efforts by enabling better resource management and energy efficiency. Smart grids, for example, will optimize electricity usage, reducing waste.

- Industry Specific Applications: IIoT will be increasingly tailored to the unique needs of specific industries. Healthcare, agriculture, and smart cities will see substantial growth in IIoT applications, improving patient care, crop management, and urban planning.

- Data Privacy and Regulation: As IIoT generates massive amounts of data, concerns over data privacy will persist. Governments and regulatory bodies will introduce measures to protect individuals' privacy and ensure responsible data handling.

- Consumer Adoption: The impact of IIoT will not be limited to industries. Consumers will experience the benefits of smart homes and connected devices that enhance convenience and quality of life.

- Global Expansion: IIoT adoption will expand globally, with developing countries catching up in implementing IIoT solutions to improve infrastructure and industrial processes.

Conclusion

In conclusion, the Industrial Internet of Things stands at the forefront of a digital revolution that is reshaping industries and ushering in unprecedented levels of efficiency and connectivity. It represents the convergence of information technology and operational technology, making it a critical element of Industry 4.0. Unlike the broader Internet of Things (IoT), IIoT is primarily focused on industrial applications, with a strong emphasis on safety, efficiency, and sustainability.

IIoT operates through a well defined architecture, involving edge devices for data collection, a network layer for data optimization and routing, and a cloud layer for in depth analysis and insights. It offers a multitude of benefits, including improved efficiency, increased production capacity, reduced errors, predictive maintenance, enhanced worker safety, energy cost savings, and improved customer experiences. However, IIoT also comes with its share of challenges, including security risks, integration complexities, data management, skills gaps, interoperability issues, scalability concerns, and bandwidth limitations. To fully harness its potential, organizations must address these challenges through robust security measures and innovative solutions.

The future of IIoT holds great promise, with advancements in automation, 5G connectivity, edge computing, AI and machine learning integration, enhanced security, and sustainability efforts. Industry-specific applications, data privacy regulations, consumer adoption, and global expansion are also on the horizon.

As the Industrial Internet of Things continues to evolve, it will undoubtedly reshape the industrial landscape, making processes more efficient, reducing costs, and improving the overall quality of life for individuals and industries alike. It is a technology that will continue to drive innovation, disrupt traditional business models, and pave the way for a smarter and more connected world.

Explore more from SolisPLC

Start learning for free

Get started with PLC programming with our forever free courses